➡️ Le cas de la centrale électrique à cycle combiné au biogaz de Montauban-de-Bretagne.

Conçue et exploitée par ENGIE BIOZ, la centrale de cogénération a été mise en service en 2017. Elle produit 9,4 GWh d’électricité verte, soit l’équivalent de la consommation annuelle d’environ 2 000 foyers, ainsi que de l’énergie thermique contribuant au chauffage des serres maraîchères attenantes (> 6 GWh).

Le méthaniseur peut « ingérer » jusqu’à 98 tonnes par jour d’intrants, dont 60-65 % d’origine agricole (effluents), 30-35 % d’industries agroalimentaires, 5 % des collectivités.

Ce projet a une réelle valeur pour l’écosystème agricole, dont l’utilisation du digestat par 43 exploitations sur une surface d’épandage totale de 2 752 ha. Ce sont 190 tonnes d’azote ainsi redistribuées sur le territoire en substitution partielle aux engrais minéraux importés.

Au niveau environnemental, ce sont 5 000 tonnes de CO2 évitées par an.

La centrale de Montauban-de-Bretagne illustre l’intégration de la méthanisation dans les territoires en rassemblant les différents acteurs économiques, exploitants agricoles et industries alimentaires, la commune ainsi que la communauté de communes de Saint-Méen-Montauban, les exploitants des serres maraîchères et le gestionnaire de réseau électrique Enedis.

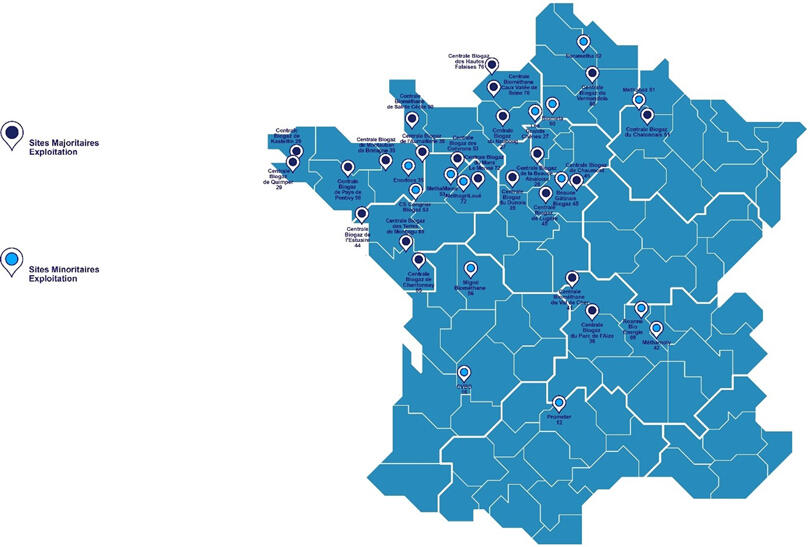

Développement en Europe

ENGIE consolide sa présence en Europe par des acquisitions au Royaume-Uni (4 unités de production) et aux Pays-Bas (2 unités).

Au total, notre capacité de production annuelle installée s’élève à 1,1 TWh de biométhane au 30 juin 2024.