There were numerous challenges in achieving this feat, especially concerning material resistance. Unlike natural gas, hydrogen has a faster and hotter flame, which also necessitated adapted safety measures.

Promising Prospects for Industrial Decarbonization

This demonstration, conducted as part of the HyFlexPower project on the premises of a Smurfit Kappa paper mill, a global leader in paper packaging, near Limoges, France (in the heart of the country), opens extremely promising prospects for industrial decarbonization, a central focus of ENGIE's strategy.

Committed to the energy transition, the Group supports its clients with solutions that enable them to:

- Reduce consumption through energy efficiency actions.

- Make their heat, cold, steam, or other utilities greener by primarily using locally available energies.

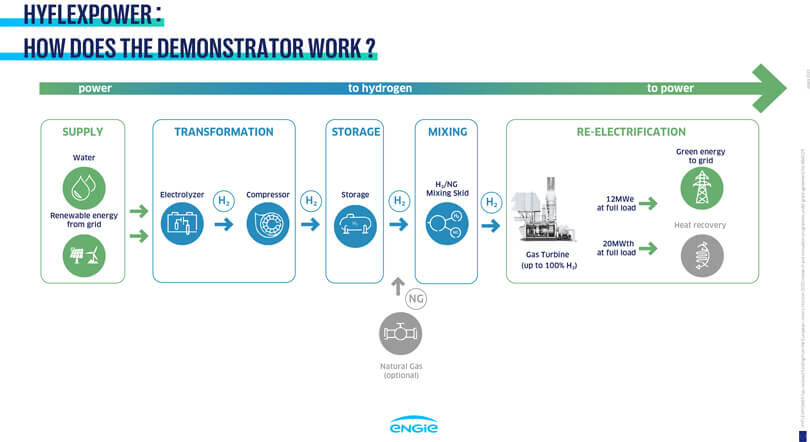

This ambitious program, initiated three years ago, demonstrates in real-world conditions (not just in the laboratory) that electricity generated from renewable energy can be transformed into green hydrogen, which can then be easily stored to power a turbine that will reconvert it into electricity for use during periods with no wind or sun. This is referred to as a Power-to-Hydrogen-to-Power demonstrator. This technology can serve industrial sites by supplying them with electricity derived from renewable sources like solar or wind.

A remarkable success for ENGIE, which, with its 200 dedicated employees working on renewable hydrogen and its derivatives, aspires to be a leader in this rapidly expanding field. Used to decarbonize the most energy-intensive industries (such as refineries, cement plants, steel production) and heavy mobility (aviation and maritime transport), decarbonized hydrogen is a key technology for achieving climate goals.

A Team Effort Supported by the European Commission

The project became a reality thanks to a fruitful collaboration among various industrial players, academic institutions, and research institutes within the HyFlexPower consortium. ENGIE Solutions built the demonstrator, the hydrogen production facilities, and ensured its commissioning and trial management, in partnership with Centrax and the German group Siemens. The latter also provided the electrolyzer and gas turbine. The German Aerospace Center and four European universities contributed to the technological development of the hydrogen turbines.

This project, with a budget of €15.2 million, was funded two-thirds by the European Commission through the Horizon 2020 program.

Building on this success, the consortium plans to expand its operations to produce both electricity and industrial heat. The decarbonization of heat being a significant challenge for industries.