What is the HyGreen Provence project?

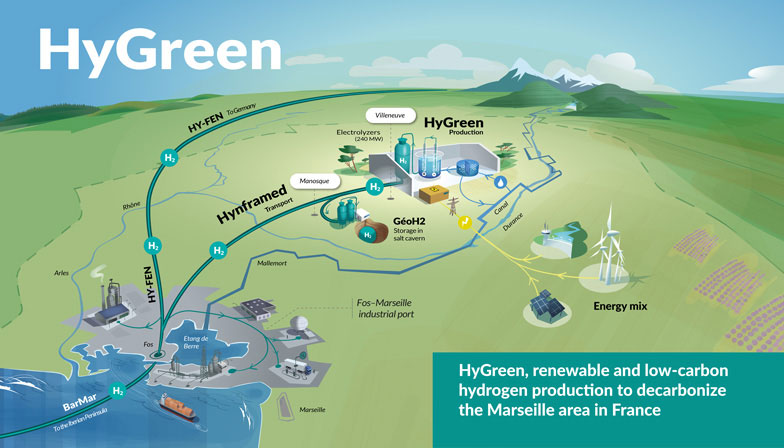

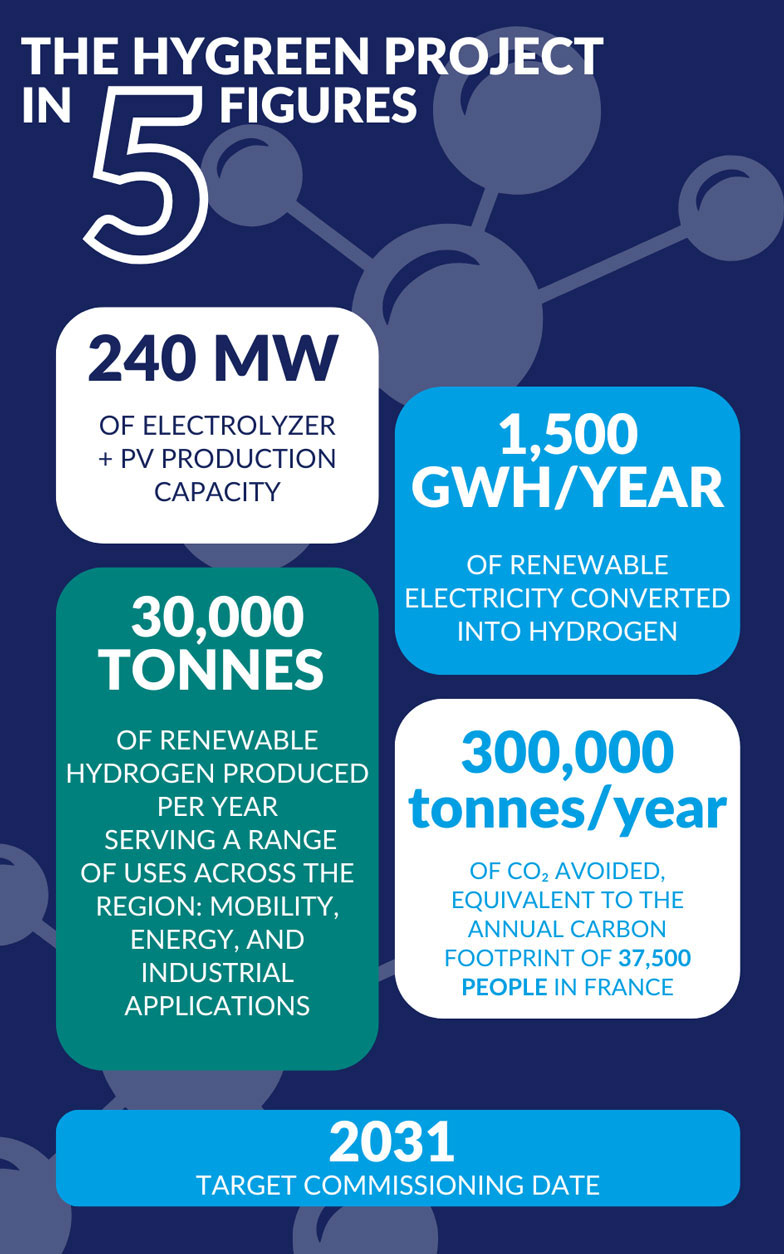

The HyGreen project involves the construction of a 240 MW renewable and low-carbon hydrogen production plant by 2031, with at least 100 MW dedicated to providing flexibility services to the electricity grid. The facility will be connected to the GeoH2 salt-cavern storage site located in Manosque, as well as to the European hydrogen network (H2 Backbone) via Fos-sur-Mer, thereby strengthening the resilience of the European energy system.

ENGIE has partnered with the Durance Luberon Verdon (DLVA) intermunicipal authority to jointly develop the HyGreen project. The objective is to produce 30,000 tons of renewable hydrogen per year starting in 2031, avoiding at least 300,000 tons of CO₂ emissions annually. This will be the first commercial-scale project of this size in France.

The hydrogen produced by HyGreen will be stored in underground salt caverns as part of the GeoH2 project. These two projects will be connected to NaTran’s hydrogen network from Manosque to Fos-sur-Mer (HYnframed network), and to the HY-FEN backbone running from southern France to the German border.

Hydrogen production and access to storage will contribute not only to the decarbonization of the local industrial base, but also to the security of energy supply in the area.

What is the main value of this project?

HyGreen Provence supports the region’s energy transition by contributing to the decarbonization of its industrial activities. As a flexibility asset, HyGreen will also play a crucial role in stabilizing the congested electricity grid in the South Region.

How does HyGreen contribute to power system flexibility?

Hydrogen production via a 240 MW electrolyzer helps balance the grid by valorizing surplus electricity and providing services to the power system. In addition, storage increases the competitiveness of hydrogen on a growing market while ensuring secure supply for industrial customers.

What is the impact on water consumption?

Producing 1 kilogram of hydrogen requires 14 liters of water, of which 4 liters are discharged after hydrolysis. This results in a net water consumption of 10 liters per kilogram of hydrogen produced.

The HyGreen project aims to produce 30,000 tons of hydrogen per year, requiring 300,000 m3 of water. By comparison, in 2022 the South Region produced 155.2 million m3 of water for local uses. The project therefore represents an increase of just 0.1% in regional water consumption.

What are the environmental benefits?

Renewable hydrogen production will replace carbon-based hydrogen, avoiding at least 300,000 tons of CO2 emissions per year in the South Region.

This hydrogen could also replace natural gas currently burned at the nearby Combigolfe thermal power plant, which has adapted its facilities for this purpose.

What is the project’s status?

The next steps include more in-depth engineering studies, with a feasibility study planned for 2026 and a FEED (Front-End Engineering Design) study scheduled for 2027–2028.

These phases will refine the project’s technical and economic profile, support the search for additional financing, enable the submission of environmental and construction permit applications, and finalize commercial agreements with industrial customers, with production expected to start in 2031 and an operational lifespan of at least 20 years.

| Following the Fos-Berre-Provence public debate (April–July 2025), ENGIE and RTE published their decisions on HyGreen, incorporating the lessons learned and recommendations from the consultation. |