The Group positions itself regarding its customers, partners and society in general, as a player in the circular economy, by producing a renewable energy such as gas or electricity and underlying services, or by offering carbon-free solutions.

Context

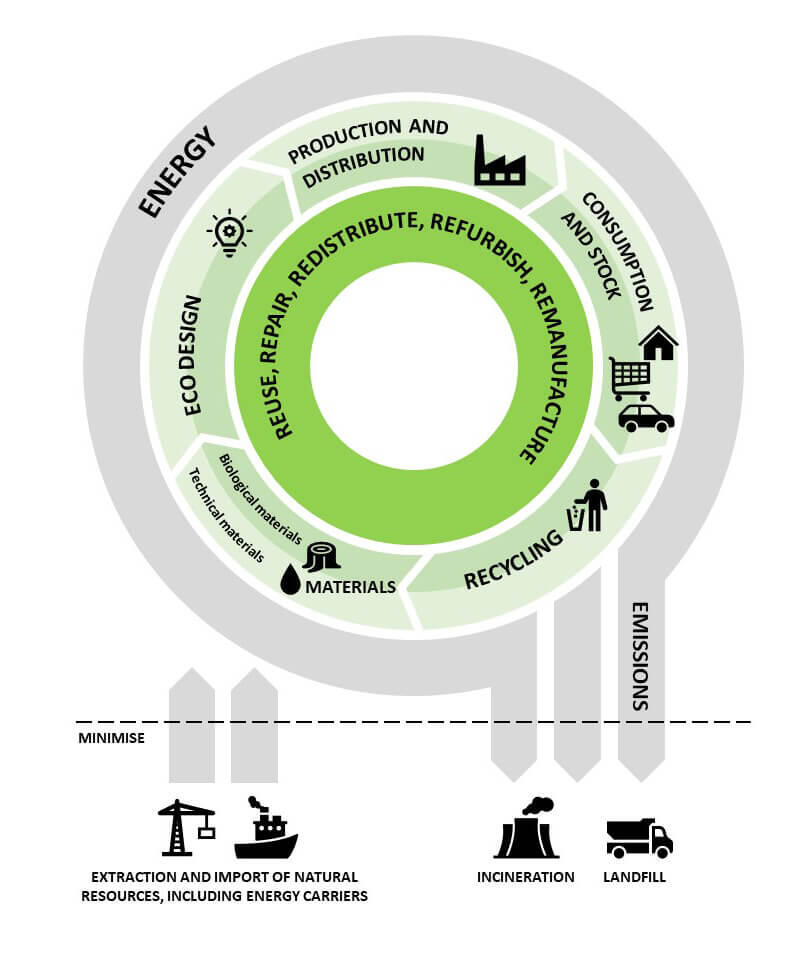

Energy is one of the important flows of the circular economy. ENGIE is therefore at the heart of possible solutions for the preservation of resources, the reuse of energy such as biomethane production or heat recovery.

The diagram below illustrates the place of energy in the loop of the circular economy.

Incorporating the recommendations of an internal audit on waste management, ENGIE has since translated, in its environmental policy, its desire to reduce the quantities produced and increase the rate of recovery of its waste.

The commitments of the Group

On 1 February 2017, under the coordination of the AFEP (the French Association of Private Enterprises), the ENGIE Group, along with 32 other French companies, has undertaken three engagements to develop the circular economy:

- Boosting renewable gases: biogas, first, second and third generation biomethane in France

- Develop energy recovery on industrial and tertiary processes

- Tooling innovatively to help decision-making process relating to circular economy in industrial zone (BECIRCLE tool: action completed in 2021)

In 2022, ENGIE has strengthened these commitments with 3 new objectives:

- Biomethane development in Europe

- Reducing the quantities of waste disposed of (hazardous and non-hazardous)

- Recycling of work clothes

Find out more about the Group’s commitments

Through its Circular Economy policy , ENGIE is committed to..:

- Increase the recycling rate of waste generated by industrial activities

- Develop green gases such as biomethane and hydrogen

- Identify recycling channels and thus reduce the impact on resources, particularly for renewable solar and wind energies

- Use resources sustainably via certified or labeled channels (e.g. biomass)

- Combat deforestation in the supply chain and use only biomass from sustainably managed forests as defined by the SBP (Sustainable Biomass Program) standard.

- Promoting the re-use of spare parts and stock circulation within the Group via a dedicated platform (BeeWe)

Joining a circular economy in action

BE CIRCLE : a European collaborative project on territorial industrial ecology

BE CIRCLE has been developed within a European collaborative project as a service for industrial companies and their ecosystem. It aims to facilitate their transition to a circular economy.

Based on a modelling platform, the tool aims to:

- develop synergies between businesses to save resources and make economic gains

- decarbonize industrial activities

- optimize the footprint

An innovation for the photovoltaic industry

ENGIE Green is a partner of the start-up SOLREED, incubated at the CEA, which proposes to extend the lifespan of solar panels by developing repair solutions combined with monitoring and a specific maintenance process.

Circular Deal : a day in favour of the circularity of renewable energies

On October 18, 2023, the Renewables GBU (R-GBU) reinforced its commitment as a leader in the energy transition built on circular business models. From setting concrete targets to key performance indicators and industrial partnerships, the R-GBU aims to increase the number of circular initiatives in renewable energies, reinforcing the messages conveyed by the Group. To this end, together with GEMS, it brought together its main suppliers and the International Energy Agency in October 2023 to identify avenues of cooperation aimed at reducing its critical materials requirements and increasing circularity in RE.

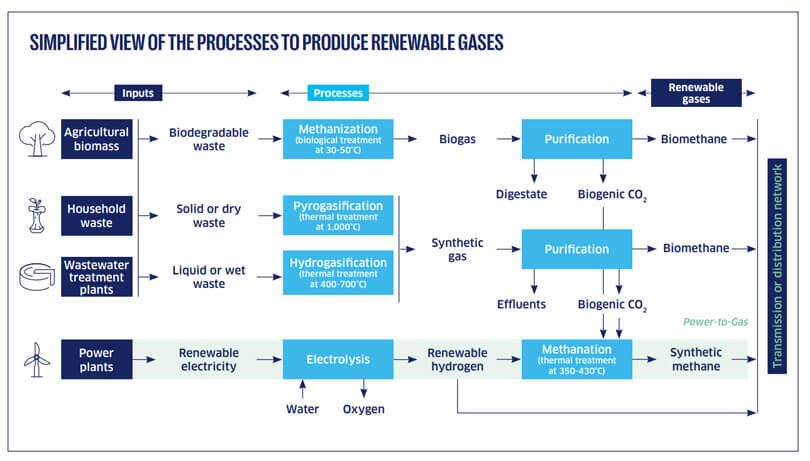

Biogas and biomethane : two essential energies for the circularity of the gas chain

The diagram below summarizes the first, second and third generation biogas and biomethane production processes.

ENGIE has set itself ambitious targets for 2030:

- 10 TWh/year of biomethane production capacity in Europe

- 50 TWh/year of biomethane injection capacity on the networks in France

In France, ENGIE has set itself the goal of greening the gas industry to achieve 100% renewable gas by 2050. The Group is present throughout the entire biomethane chain, from the development of industrialization projects to distribution.

In France, ENGIE initiates, develops, finances, builds and operates units for injecting biomethane into the gas grid, with a long-term commitment to local communities. In the United Kingdom, the Group acquired Ixora Energy Ltd, a biomethane producer, in September 2023, demonstrating its desire to become a European player in the biomethane market.

The energy produced is used to supply thousands of homes, thereby reducing CO2 emissions. At the same time, the Group adapts its infrastructures to biomethane injection, and develops efficient, low-carbon solutions at the end of its value chain (such as hybrid heat pumps for heating, or high-performance engines for land and sea mobility), enabling customers to support the greening of their consumption.

Find out more

ENGIE is also committed to animal welfare by paying particular attention to the practices of our livestock partners. ENGIE adapts to their practices, not the other way around. For example, ENGIE does not encourage livestock to be kept in buildings in summer instead of grazing, as evidenced by the stable volumes of effluent delivered to our sites. These are in any case a small part of our agricultural supplies and keeping them in the summer would generate additional income or minimal digestate, not covering the extra cost of such a practice.

Second-generation biomethane projects

Hydrothermal gasification: producing biogas from liquid waste

ENGIE New Ventures has invested in the startup TreaTech, whose technology enables the conversion of industrial liquid organic waste and municipal wastewater into biogas. It offers several competitive advantages: a rapid reaction time (just a few minutes compared to several dozen days for methanisation), a small footprint, as well as the ability to eliminate bacteria, viruses, and pathogens, and to treat plastic microparticles (including PFAs, the "eternal pollutants"). This solution is the result of work by the Sustainable and Catalytic Processes Laboratory at the Swiss Federal Institute of Technology in Lausanne and the Paul Scherrer Institute in Villigen.

Hydrogen : an accelerator of decarbonisation of the energy chain

To achieve a carbon-neutral future, ENGIE has launched an ambitious program to develop hydrogen production, transport, storage and distribution capacities. This gas can be produced from locally-established renewable energies, thus promoting short energy circuits and local jobs. Hydrogen is therefore the promise of a new technological, energy and industrial sector, both locally and globally, with new jobs at stake, essential for contributing to the circular economy.

ENGIE’s hydrogen objectives:

- 4 GW of hydrogen production capacity through electrolysis by 2035

ENGIE is stepping up its commitment to hydrogen development, notably at the HyVolution trade show.

Find out more

Biofuels : an asset for the decarbonisation of transport

Biofuels are alternative fuels obtained from biomass, i.e. from non-fossil raw materials of plant, animal or waste origin. They emit 50% less CO2e than their fossil equivalents, making them a major asset in the decarbonization of liquid fuels.

In Valenton, Val-de-Marne, the "BioGNVAL" pilot project launched in March 2015 involves transforming sewage sludge from the Paris region into liquid biomethane, which can be used as a fuel for trucks. An ecological, economical fuel that guarantees a high degree of autonomy.

Preserving natural resources

New commitment on energy crops used for production of biomethane

In 2024, in response to concerns about the use of agricultural inputs in biogas production, ENGIE is committed to limiting the use of energy crops in biogas production.

The new biomethane production units built by ENGIE (greenfield projects) must use a very low proportion of energy crops. The proportion of energy crops in the annual tonnage of inputs at the country scale must be single-digit.

Where ENGIE acquires existing biomethane installations operating with energy crops (brownfield projects), a plan to gradually phase out energy crops, as soon as possible and at the latest within 10 years (just transition for farmers) is implemented. If there are still inputs from energy crops, the average annual tonnage in the total portfolio of the country should be no more than single digit in percentage terms.

Find out more

Managing the use of critical materials and rare earths

Critical materials are raw materials used in certain equipment purchased by ENGIE to produce decarbonized electricity, which present supply risks of an economic, geopolitical, environmental or human rights nature.

Certain so-called rare earths are among these critical materials since they have become indispensable for certain low-carbon technologies (electric batteries, magnets for certain wind turbines, electrolyzers for hydrogen production, etc.) due to their exceptional properties: high thermal stability, high electrical conductivity and strong magnetism.

At this stage, ENGIE considers that geostrategic, human rights and environmental risks are the main issues to be addressed around these rare earths and intends to deepen its analysis of the negative impacts of their extraction and their reusability potential with the help of experts or within the framework of partnerships with suppliers of equipment using these materials.

In 2022, ENGIE drew up a global internal action plan for critical raw materials, known as the CRM (for Critical Raw Materials) plan, to anticipate future tensions and mitigate critical materials risks over the period to 2030. The CRM action plan includes measures linked to supply chain management, industrial partnerships, lobbying and the scaling-up of circular economy models.

The focus is on improving supply chain traceability. In addition, ENGIE Research has developed a tool that provides a comprehensive overview of the specific risks associated with each key material: the Material Risks Passport. In 2024, four technologies were analysed: wind, solar PV, battery energy storage, and electrolysers. In 2025, four other technologies will be studied.

End-of-life management and secondary sourcing offer enormous potential for mitigating the risk of supply chain bottlenecks, reducing our dependencies and limiting the environmental impact of our fleets. That's why ENGIE is leveraging its expertise in component dismantling/reuse/recycling to pave the way for a circular approach to renewable energies, in close collaboration with our industrial partners.

Zebra or the wind of innovation to preserve resources

In late 2023, the Zebra consortium of six partners, including ENGIE, unveiled a second recyclable thermoplastic wind turbine blade. This new 77-meter-long blade includes a component made from recycled Elium® resin and a new adhesive that is also recyclable. It offers the same mechanical performance, lightness and strength, as the thermoset materials used in current blades. The added advantage is that it can be recycled through a variety of channels. The first prototype 62 m fiberglass blade was produced in early 2022 and underwent mechanical performance tests. In October 2024, the Zebra project successfully recycled the “Elium” resin and the Ultrablade fabrics from wind turbine blades and production waste, turning them into reusable materials. This closed-loop process addresses the growing challenge of end-of-life blade management in the wind industry.

Reducing waste

ENGIE believes that reducing waste is a promising voice for the sustainable development of its operations. As a result, the Group has set itself targets for reducing its hazardous and non-hazardous waste by 2030 with the ambition of increasing its recovery every year.

| Indicators | 2022 | 2023 | 2024 | 2030 target |

| Reduction in the quantity of non-hazardous waste disposed of vs 2017 | -47% | -73% | -63% | -80% |

| Reduction in the quantity of hazardous waste disposed of vs 2017 | -91% | -93% | -92% | -95% |

In 2024 ENGIE achieved an 85% recovery rate for non-hazardous waste (versus 83% in 2022) and a 22% recovery rate for hazardous waste (versus 24% en 2022).

When worksite clothing becomes a thermal or acoustic insulator

ENGIE Solutions’ technicians contributed to the recycling and valorisation of their used workwear totalling 1,421 kilograms in 2023, i. e. more than 2,000 workwear. This record collection was enhanced with the support of two partners: MOLINEL (via the Second Life Device) and Triethic. Used garments have been transformed either into frayed garments intended to become thermal/sound insulators (especially for the construction industry), or into solid recovered fuels. Launched three years ago, this retraining operation reinforces its success year after year, thanks to the growing involvement of all employees in promoting a more circular economy.