Veuillez accepter les cookies "marketing" pour voir cette vidéo.

Ch0C is an industrial boiler capable of capturing 90% of the CO₂ emissions produced during natural gas combustion. The first demonstrator, installed at the Villers-Saint-Paul chemical platform in France, was commissioned on June 25. It is operated by ENGIE Solutions. The goal is to bring the boiler to market as early as next year.

As a result of a collaboration among 16 partners from across the value chain (energy providers, engineers, and manufacturers) including ENGIE Solutions and ENGIE subsidiaries NaTran and GRDF(*), this innovation is backed by the France 2030 plan and energy transition agency Ademe (affiliated with the French Ministry for the Ecological Transition).

Ch0C represents a breakthrough in decarbonizing industrial steam production in two ways:

- By replacing air with oxygen during combustion (a process known as oxycombustion), the boiler’s performance is significantly improved at a competitive cost.

- The process also makes it easier to capture CO₂ emissions at the boiler’s outlet, either to reuse or to store them, since the flue gases are made up almost entirely of CO₂ and water.

This latter aspect represents a major asset in the capture of CO₂, which is known to be difficult.

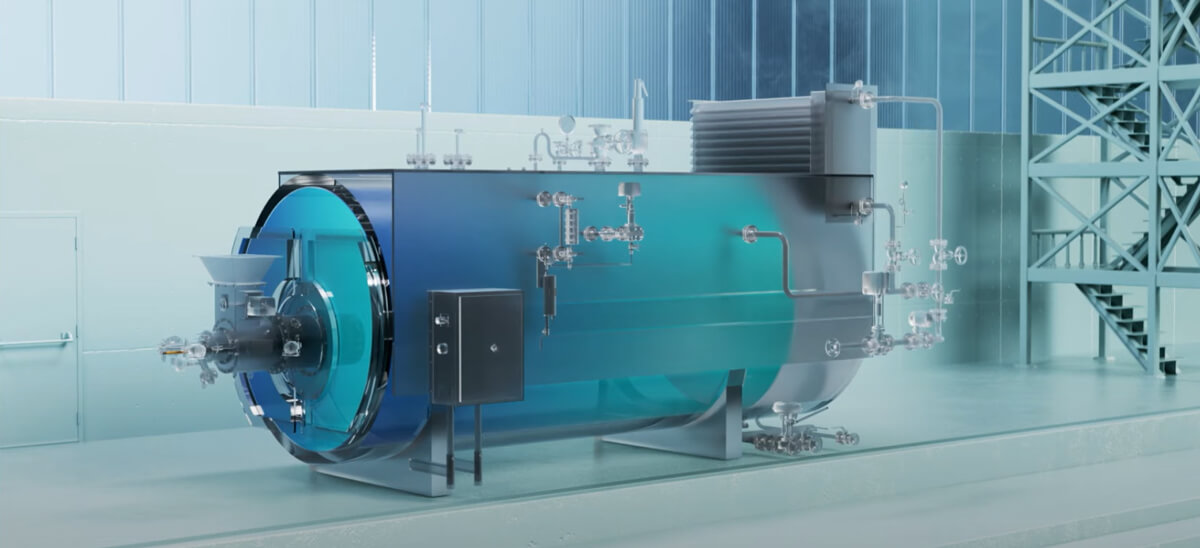

Gas boiler Ch0C

Strong decarbonization potential

Ch0C’s key achievement lies in combining multiple complementary technologies, for the first time, to make near-complete decarbonization of gas boilers possible at a cost comparable to biomass boilers.

Replacing 2,000 industrial boilers with Ch0C units—particularly in the food, chemical, and pulp & paper sectors—could cut CO₂ emissions by 8 million tons per year, which represents about 10% of France’s industrial emissions. It targets manufacturers for whom electrification is not a viable option due to process or cost constraints.

Ch0C marks the emergence of a high-performance technology sector dedicated to industrial decarbonization—and meets the growing demand from industry players.