R&D: the key to the emergence of new renewable energies

According to the International Energy Agency, three-quarters of the efforts made to cut greenhouse gas emissions will have to come from immature technologies1. Consequently, R&D is playing a crucial role in the emergence of these “new” renewables. Every year, the Group spends €190 million on R&D and employs more than 900 researchers in this activity. Our corporate R&D centres are focussing on green gas and green electricity technologies, which are both essential resources to reach carbon neutrality of our energy system. Every one of these resources is perceived as a global, reliable, sustainable and profitable energy solution for our customers.

“Working on a variety of technologies related to energy production, transport, storage and use is crucial.”

Dr. Jan Mertens, Scientific Director, ENGIE Research (Report on Emerging Sustainable Technologies)

Biogas and biomethane: targeting 100% of green gases

Biogas and biomethane are two of the solutions being targeted by France and Europe to decarbonize. ENGIE intends to achieve these ambitions, in terms of both the technology and their implementation on an industrial scale.

The Group has already committed to investing €800 million in biomethane between 2018 and 2023, and plans to increase this amount to €2 billion by 2030. This goal is to produce 5 TWh of biomethane, which represents the annual gas consumption of 400,000 households. Here again, the new channels of production will be made viable by slashing production costs by 30% by 2030. On the development front, our GAYA project in Saint-Fons, France already uses non-recyclable solid waste as a raw material to produce green gas by pyro-gasification2. These major scientific advances are creating opportunities to recover this type of waste by developing new industrial solutions.

A change is in the air for floating offshore wind turbines

Floating offshore wind turbines are still in their infancy. The first farms are now appearing, including WindFloat Atlantic in Portugal, or the floating wind turbines that will be installed off the coast of Leucate Le Barcarès in the Gulf of Lion by 2022. This technology is very promising. How does it work? Wind turbines installed on floating structures measuring 20 to 25 metres are towed out to sea by tugs. Located between 15 km and 22 km offshore, they can harness the full force of sea winds. A single underwater cable conveys the electricity produced back to the shore. Floating offshore wind turbines have a bright future. They have huge potential, because floating wind turbines can be installed in places where the sea is 50 to 200 metres deep, while fixed offshore wind turbines are limited to depths of 50 metres. Today, ENGIE is a key player in the development of floating offshore wind turbines, thanks to Ocean Winds, its joint venture that operates in Europe and the United States.

The conditions required for green hydrogen to take off

ENGIE intends to become the leader in renewable hydrogen, which is produced on a large scale from renewable energy sources (wind and solar power, hydroelectricity, etc.). Huge investments are being made in green hydrogen, which has a significant decarbonization potential3, in an effort to make it as competitive as grey hydrogen, which is produced from fossil fuels. Production costs will be cut by creating channels of industrial production and improving the production techniques, in a movement supported by the French government as part of its energy transition policy.

Green hydrogen: the key to carbon-free consumption

The development of green hydrogen demands a strong command of its entire value chain, from its production by the electrolysis of water, to its applications in industry, transport and the storage of green energy. Two solutions are currently being developed: on-site industrial production, which offers our customers the possibility to use the green hydrogen directly, and conversion into hydrocarbons, such as synthetic methane (combined with carbon dioxide), which can then be stored.

With the worldwide producer of fertilizers, Yara, we plan to convert the Yuri plant in Australia to produce ammonia from renewable hydrogen, which is its raw material. This 5-year project will make Yuri one of the largest plants producing renewable ammonia.

Through its subsidiary Storengy, ENGIE is also developing power-to-gas technology, which consists of producing synthetic hydrogen or methane from excess renewable electricity, storing it, and then re-injecting it into the natural gas network at the request of our customers. Power-to-gas was successfully tested in the field between 2018 and 2020 in northern France by our GRHYD project. We succeeded in decarbonizing the gas in the distribution network of a housing estate in Dunkirk by injecting a variable portion of between 0% and 20% of hydrogen.

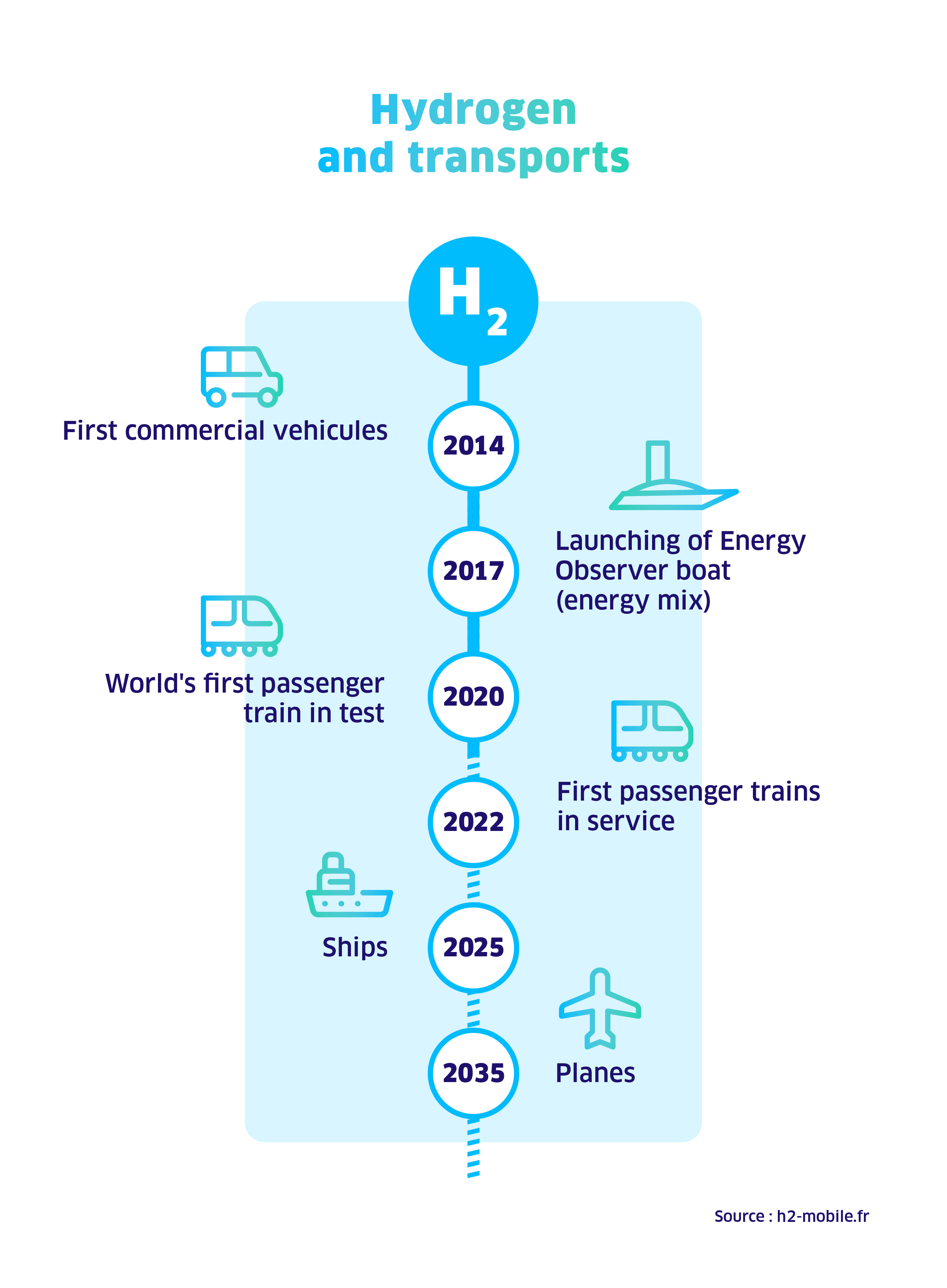

ENGIE is well positioned for the deployment of green hydrogen on an industrial scale in 2025 thanks to several experimental projects in France and worldwide in the fields of heavy mobility (trucks, trains, ships) and intensive mobility (light commercial vehicles, for example). Since 2019, the

ENGIE is well positioned for the deployment of green hydrogen on an industrial scale in 2025 thanks to several experimental projects in France and worldwide in the fields of heavy mobility (trucks, trains, ships) and intensive mobility (light commercial vehicles, for example). Since 2019, the